General

Space frame systems are three dimensional structures which are constructed by connecting straight tubular struts to each other with the use of solid spherical hubs. Production is completed at the factory and the assembly is made at the construction site. Space frame members are struts, spherical hubs, bolts, purlins and supports.

STRUTS

The material of the struts are convenient with DIN 17100 (EN 10.025) and it is steel St37-2 (material no: 1.0037). It can be between 42 mm and 324 mm according to the necessity.

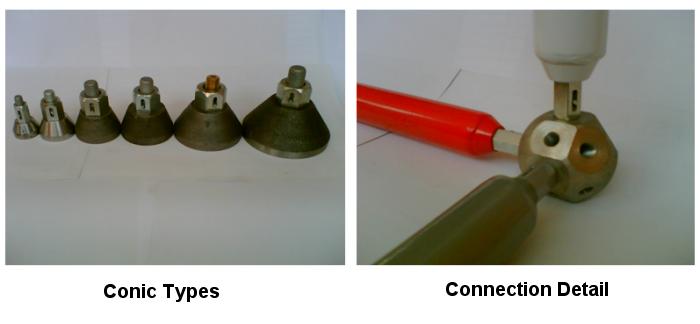

The conic parts are made with the same material with struts. It is welded by using type SG2 weld wire to the strut edges convenient with DIN 4100, DIN 4115 (EN 440, EN 758,EN 1668).

There are conics, bolts, nuts and pins at both ends of pipes and we put mounting numbers on each pipe .

Spherical Hub

The solid spherical hub is made from C45 steel material via forged convenient with the DIN 17200 (EN 10.083). Sphere diameter changes between 60 mm and 240 mm according to the design.

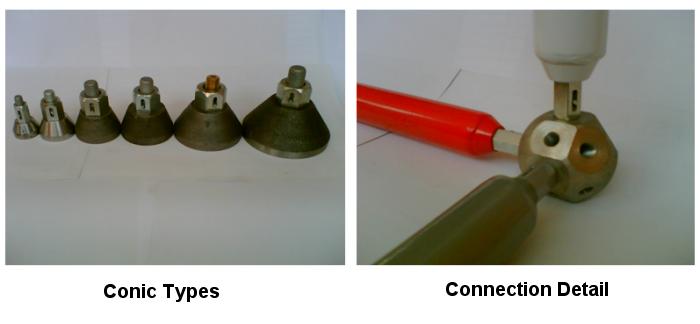

To connect the struts with the spherical hub, gear bolt bores are made on to the spherical hub. The size and the number of bores on to the hub are determined according to the specifications of space frame system. Bore entries are flattened by a milling process to ensure proper connection to the tubular struts.

Bolts

The bolts which are used are the quality of 8.8 or 10.9 convenient with DIN 1654 and DIN 17200 (EN 10.083). Bolt diameters can be between 12 mm and 72 mm. Bolts are ISO threaded bolts in accordance with DIN 13 and they meet the standards of DIN 267.

For 8.8 quality bolts min.ultimate-strength is 80 kg/mm², min.tensile-stress 64 kg/mm² min.ultimate-strain %12

For 10.9 quality bolts min.ultimate-strength is 100 kg/mm², min.tensile-stress 90 kg/mm² min.ultimate-strain %9

Purlins and other members : Purlins, columns, beams and others are made of St-37.2 steel material. The members have I, U, C or box section.

Supports

Shape and dimensions of the supports are various according to the systems specifications. Supports can be fixed, free in one direction or free in two directions. Supports are made from St-37 or St-52 steel material.

Resistance against corrosion

The members are cleaned from rust-oil stains by mechanical or chemical methods and then members are coated as below:

a) By using electrostatic powder paint (80 micron) at RAL colour, as required

b) By hot dipping galvanizing process

c) By hot dipping galvanizing process+RAL colour (as required) electrostatic powder paint.

Spherical hubs and bolts are covered by 15 micron electron galvanize.

Assembly

The assembly can be made very easily by using simple manual tools as below :